When it comes to turbo engines it seems everyone just wants “a little more boost”. We get it, more boost almost always equals more fun, as long as more boost comes with supporting mods, high octane fuel and ecu tuning that is. Below we will get into the nitty gritty details of internal & external wastegates, how they control boost pressure and the different versions available.

How Internal Wastegates Work

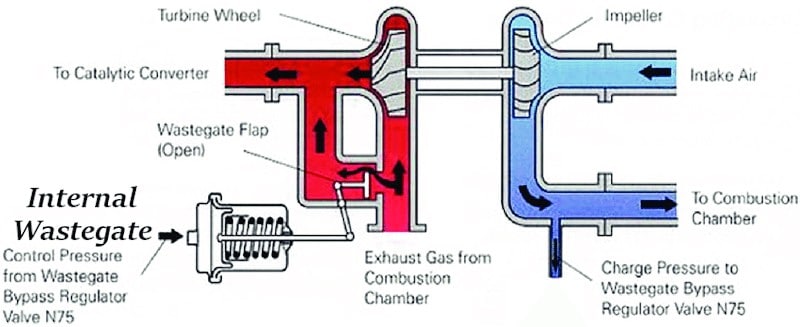

The wastegate on a turbocharged internal combustion engine is used to bypass exhaust away from the turbine wheel effectively controlling/limiting the turbos RPM and intern boost pressure. This means the wastegate plays the key role to ensure the turbo and engine run at the desired boost pressure. Without a functioning wastegate bypassing exhaust away from the turbine boost would climb uncontrollably quickly leading to damage.

There are 2 common types of wastegates:

Both internal and external wastegates are now available with boost or electric motor actuators. After about 2015 most manufacturers transitioned to using the more modern electric motor wastegate actuator while pre 2015 almost every manufacture used boost actuated wastegates. All boost actuated wastegates rely on a spring, diaphragm and boost pressure. When boost pressure overcomes the spring rate it pushes the wastegate open allowing exhaust to bypass the turbine wheel.

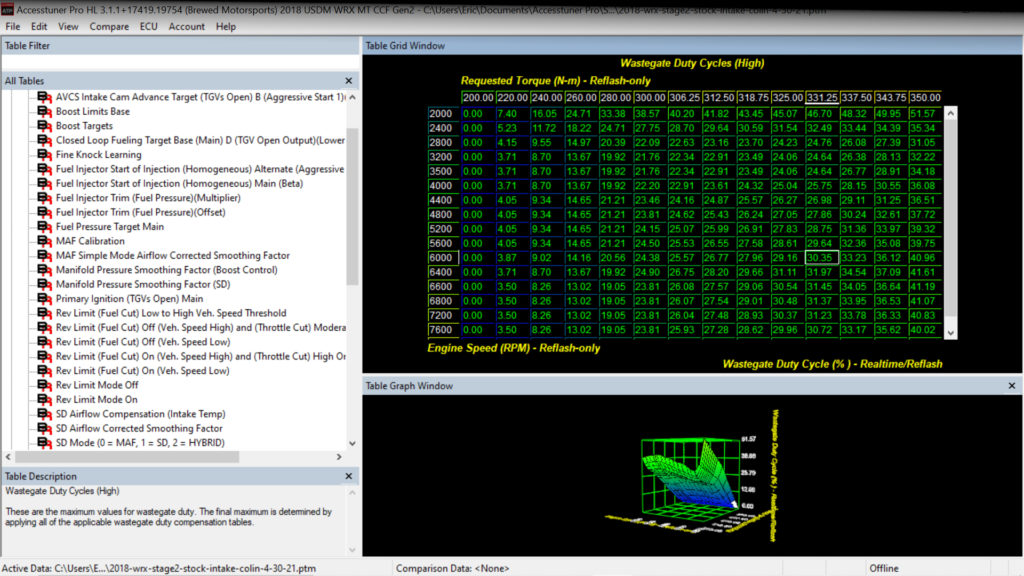

Any electric motor actuated wastegate is controlled directly by the ecu for extremely accurate/fast response when compared to the older boost actuated wastegates. Electric wastegates utilize a motor similar to what you would find in a DBW throttle body. Ensuring electric wastegates stay within their operating temperature range is extremely important.

Internal wastegates are most commonly found on OEM applications, while internal wastegates do work ok they are normally quite small and restrictive compared to an external wastegate. An internal wastegate actuator is normally bolted to a turbo. An adjustable arm connects this actuator to the internal wastegate flapper or valve that is built into the turbine housing. As boost increases/reaches target pressure the actuator pushes on the arm which opens the internal wastegate flapper and allows exhaust gas to bypass the turbine wheel.

How External Wastegates Work

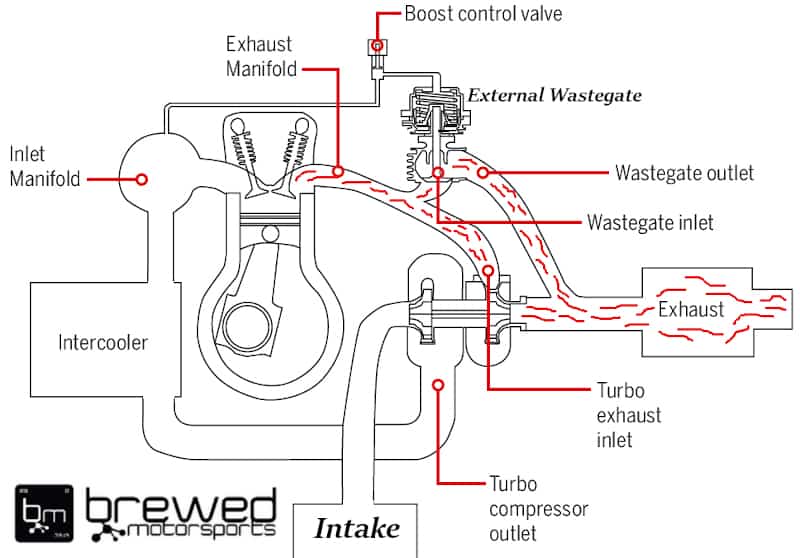

External wastegates also work by bypassing exhaust away from the turbine wheel however as the name suggests they are not built into the turbo like internal wastages. An external wastegate is a bypass valve that is mounted on the collector of a turbo manifold (just in front of the turbine housing). External wastegates have an actuator that sits directly on top of a valve inside a housing . This valve seats at the bottom of the wastegate housing effectively forcing all exhaust to the turbine wheel. As boost increases the actuator starts to lift the valve off its seat which allows exhaust to bypass the turbine wheel.

The benefits of using an external wastegate over an internal wastegate are a wider more accurate range of boost control and the ability to flow much more exhaust gas away from the turbine wheel.

Boost Creep

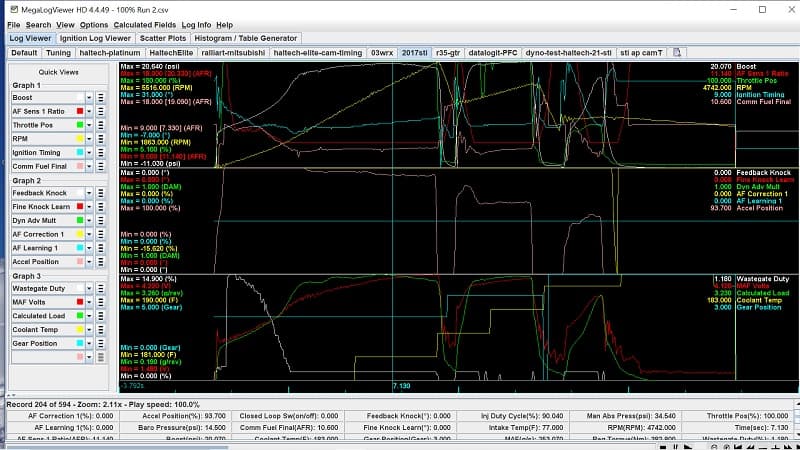

One of the most common problems caused by a mis-sized wastegate is what people commonly refer to as “boost creep”. While boost creep is most common with internal wastegates it can also happen when the external wastegate used is to small. Boost creep happens when the wastegate is fully open BUT not able to bypass enough exhaust away from the turbine wheel. When this happens the exhaust is simply following the path of least resistance through the turbine housing NOT bypassing it through the wastegate. The data log below comes from a built STI running a GTX3576R turbo kit with a Tial MVS wastegate. While the Tial MVS wastegate is a VERY good wastegate it is a bit to small for the EJ25 engine paired with an efficient turbo like the Garrett GTX35. The ideal wastegate for a 2-3 liter engine making 400-800hp would be a 44mm of 45mm external wastegate such as the Turbosmart hyper-gate on sale and linked below.

The log below has no input from the boost solenoid (less than 2% duty cycle) which means the engine will run at the lowest possible boost AKA “wastegate spring pressure”. You can see the white line (boost) climbs quickly then tries to “level off” as the wastegate opens at ~15psi. However do to the MVS wastegate being a bit to small for the EJ25 and GTX3576R turbo you can see the boost continues to climb from 15psi up to 20psi by 4800rpm at which point it starts to taper back off as the turbo becomes less efficient. 15psi creeping to 20psi or 5psi of boost creep is more than ideal, at most 2-3psi of boost creep would be considered acceptable. Now keep in mind this 5psi of boost creep happened in only 3rd gear, as the engine is loaded up/ran at WOT (wide open throttle) in 4th, 5th and 6th gear the engine will be under load for longer resulting in even more boost creep than we can see happening in the 3rd gear pull. If you look further to the right in the log you can see as the car continues to accelerate in 4th gear the boost creep becomes more severe and boost creeps over 6psi over wastegate spring pressure before 4800rpm.

The correct way to fix boost creep is to use a larger wastegate (listed below) as well as position the wastegate more directly in the flow path of the exhaust. (This often referred to as wastegate priority and you can see it on a number of the turbo manifolds and turbo kits we offer.) In most cases though a simple upgrade to an external Turbosmart wastegate will fix any boost creep issues and give you proper control of the boost so your tuner can safely tune the engine for maximum reliable power with super accurate boost control.

Below are a few of the internal and external wastegate options we highly recommend as well as plug and play ebcs (electric boost solenoid) kits for all your favorite applications. For those running standalone ECU’s check out the 4 port ebcs for maximum boost range.

-

Cobb 08-12 Mitsubishi EVO X / 09-12 Ralliart 3-Port Boost Control Solenoid$160.00

Cobb 08-12 Mitsubishi EVO X / 09-12 Ralliart 3-Port Boost Control Solenoid$160.00 -

Haltech Boost Control Solenoid 3 Port 1/8th NPT 33Hz$119.00

Haltech Boost Control Solenoid 3 Port 1/8th NPT 33Hz$119.00 -

AMS Performance Alpha Performance R35 GT-R 3 Port Boost Control Solenoid Kit for Internal Wastegate$184.25

AMS Performance Alpha Performance R35 GT-R 3 Port Boost Control Solenoid Kit for Internal Wastegate$184.25 -

Turbosmart WG45 Gen V Hyper-Gate 45 14psi Black$424.95

Turbosmart WG45 Gen V Hyper-Gate 45 14psi Black$424.95 -

Turbosmart eB2 4 Port Solenoid$137.45

Turbosmart eB2 4 Port Solenoid$137.45 -

Turbosmart IWG75 15+ Ford Mustang EcoBoost 2.3L 10 PSI Black Internal Wastegate Actuator$157.45

Turbosmart IWG75 15+ Ford Mustang EcoBoost 2.3L 10 PSI Black Internal Wastegate Actuator$157.45 -

Cobb 04-07 Subaru STI / WRX / FXT 3-Port Boost Control Solenoid EBCS$160.00

Cobb 04-07 Subaru STI / WRX / FXT 3-Port Boost Control Solenoid EBCS$160.00 -

Cobb 08-14 Subaru WRX / 08-21 STI 3-Port Boost Control Solenoid EBCS$160.00

Cobb 08-14 Subaru WRX / 08-21 STI 3-Port Boost Control Solenoid EBCS$160.00 -

GFB 44mm V-Band External Style Wastegate$377.10

GFB 44mm V-Band External Style Wastegate$377.10

Any one that wants to learn more about Electric boost control solenoids (EBCS) and how they work check out our next article. Click here if you’re looking for a new Garrett Boost Club Line G35 or G37 turbo. These new GBC35 and GBC37 turbos offer BIG performance for under $1000usd!